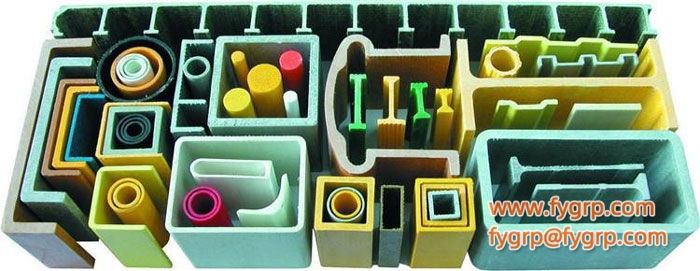

Pultrusion profiles

Pultrusion

Pultrusion process is a method of continuous production of composite material, it is an automated production process that the untwisted yarn on rack, other continuous reinforced material, polyester surface mat are impregnated with resin, then through forming mould of keeping a certain section shape, and make it heat curing in mould and forming to demould continuously, resulting pultrusion products.

Not only can FRP pultruded profile improve its performance through material selection and lamination process design, but also optimize its section and structure design to meet specific requirements.

FRP pultrusion profiles have many advantages, such as corrosion resistance, light weight, high strength, good dimensional stability, at the same time with insulation, no heat conduction, inflaming retarding, beautiful and easy maintenance features. It hardly has maintenance expenses compared with traditional materials such as steel, aluminium and wood. It is often used in chemical processing plants, marine construction, food and beverage processing, petroleum smelting, paper industry, sewage treatment and transportation, etc. Pultrusion profiles provided by FYGRP includes round rods, round tube, angle steel, square tube, channel steel, 工-steel, T –steel. Chemical platform and handrail system assembled by pultrusion profiles and moulded fittings have features of corrosion resistance, light weight, high strength, solid structure, beautiful appearance and convenient installation, widely used in petroleum chemical industry, metallurgy, electric power, etc.

Please contact tc@fygrp.com for details

![[pics:title]](/static/upload/image/20200921/1600696169952919.jpg)

![[pics:title]](/static/upload/image/20200921/1600696169616539.jpg)

![[pics:title]](/static/upload/image/20200921/1600696169865163.jpg)

![[pics:title]](/static/upload/image/20200921/1600696169869645.jpg)