Large Vessel

In addition to common FRP storage tanks of light weight, high strength, chemical resistance and long service life, large FRP vessels winding on site also have the following special advantages.

advantages:

No need to transport, easy to install: Large FRP vessel adopts site winding by production equipment to manufacture and installation, which solves the problem of inconvenient transportation.

Large volume: the maximum winding diameter of on-site FRP large vessel can be up to 25 meters, and the maximum volume can be up to 5000 cubic meters

High strength: adopt cross winding and hoop winding, ensure the bidirectional strength and overall performance of the product, which solves the weakness of axial strength caused by only hoop winding with FRP large vessel winding machine in domestic currently, ensure the best performance of FRP large vessels winding on site.

ncrease the overall interlaminar shear strength, bending strength, creep resistance, wind and seismic resistance of the large vessels winding on site.

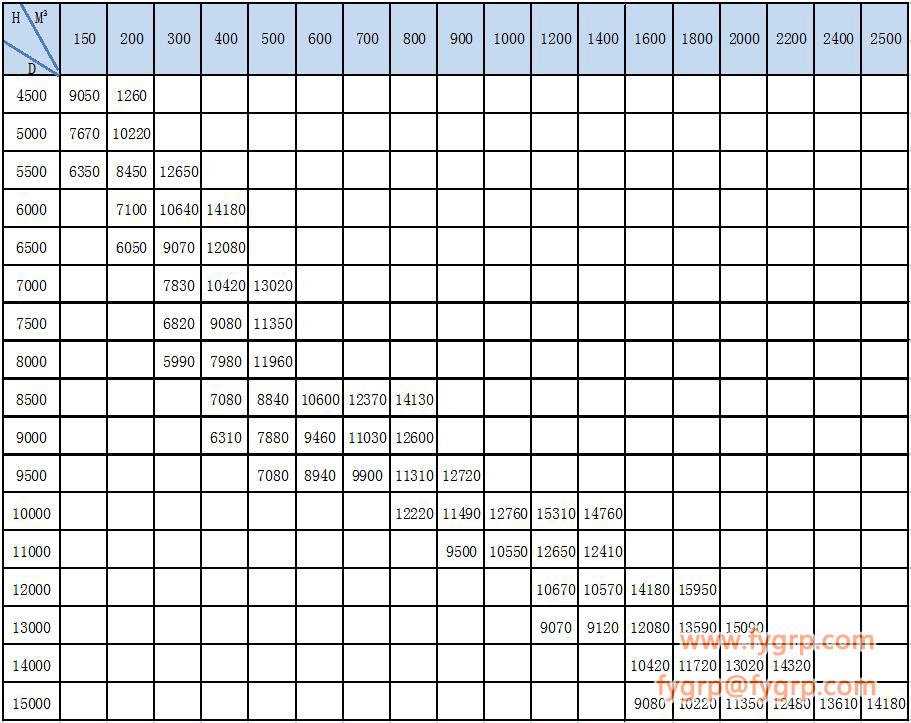

Product specifications:

Diameter: DN4000-25000mm

Volume: 75-5000 cubic meters

Pressure: Normal pressure

Application of FRP large vessel winding on-site:

--FRP large vessel winding on site of dynamic wave system for environmental protection.

--FRP large hydrochloric acid vessel winding on site

--FRP large vessel for oil field

--Sewage tanks of FRP large vessels winding on site for oil field

--Various FRP large vessels winding on-site for chemical industry

Vessel parameters table

Please contact tc@fygrp.com for details

![[pics:title]](/static/upload/image/20200921/1600669446315073.jpg)

![[pics:title]](/static/upload/image/20200921/1600669446774922.jpg)

![[pics:title]](/static/upload/image/20200921/1600669446823830.jpg)

![[pics:title]](/static/upload/image/20200921/1600669446464103.jpg)

![[pics:title]](/static/upload/image/20200921/1600669446458428.jpg)

![[pics:title]](/static/upload/image/20200921/1600669446550463.jpg)