Escape passage pipe

Escape passage pipe is a kind of composite pipe with fiberglass and thermosetting resin as base material and FRP hollow structure (Three-dimensional fiber) as reinforcing material. The domestic escape pipeline has advantages of flame resistance, wear resistance, antistatic, and impermeability etc. through technical research and development, combine with advanced technology and usage conditions abroad. All the products developed by our company are FRP material which can’t occur safety accidents caused by delamination and unstable adhesion under the influence of gravity. Our products have applied for the patent and actively participated in drafting for national standards of FRP escape pipes. We put our contribution to owners.

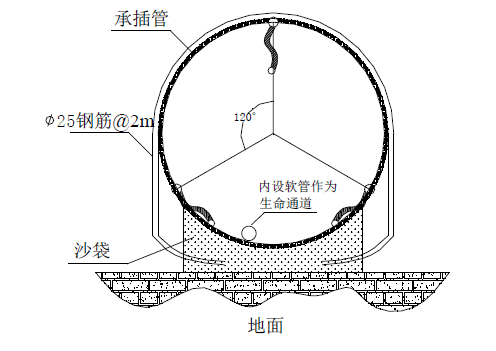

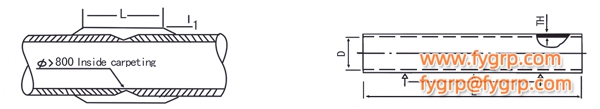

1.The inner diameter of the pipe is 80cm, the single length is 2m, and the weighs of each section is about 98kg. The stiffness of the compression ring is 18KN/m2, and the weight is 1/4 of steel pipe. Manual handling and splicing can be done without the help of construction machinery and auxiliary equipment, without normal construction of tunnels.

2.The interlayer honeycomb structure of pipe wall can absorb enormous impact force caused by impact load to ensure the inner layer of pipe has high impact resistance, good toughness, small plastic deformation, high resilience under impact load (resilience rate up to 95%~98%), reusable.

High strength, good toughness. no obvious damage to the pipe when 300 kg stone falling onto the pipe from 4 meters high; normal steel pipe is seriously deformed, can not be recovered.

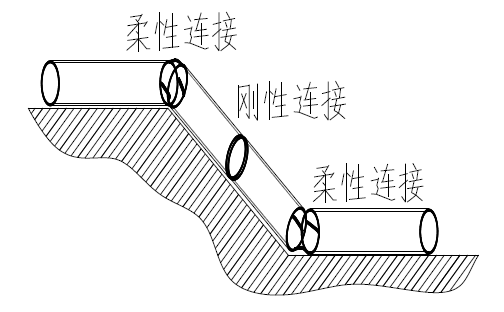

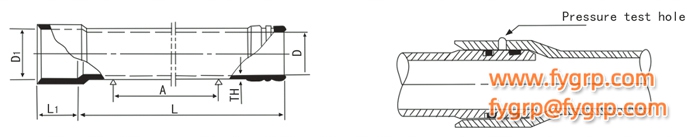

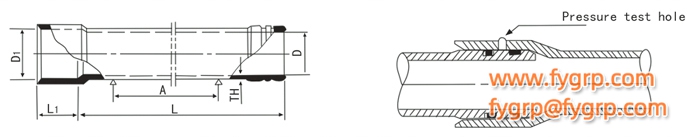

3.Adopt bell and spigot joint connection which is easy for installation with locking device, no need of welding or bolt connection.

Adopt double "O" rubber ring flexible connection, good sealing property, good differential settlement resistance, with pressure test hole, to ensure that the sealing rubber ring doesn’t leak after installation.

4.The new type of escape pipeline is provided with traction rope and hose. The traction rope is used to help the trapped people to crawl, and the hose is used as the life passage to get in touch with the outside world after the accident. Its diameter is 3cm~4cm, and its length is the distance from the palm to the second lining.

5.When using step method construction, we can set sleeve to realize turning in order to plug and pull. Add reflective stripe and fluorescent developing agent according to user’s demand to facilitate rescue work. We have spent two years in developing the internal curing process of macromolecule pipe, which is different from the common adhesive reflective stripe. The test has proved that it will not fall off within 1,000 times of usage.

6.There is salt water in the interlayer of pipe with two probes. When the pipe is damaged, salt water will flow out automatically and the liquid level will drop, then trigger the alarm device and transmit to the remote computer for cloud computing, so as to have enough time to escape.

Please contact tc@fygrp.com for details

![[pics:title]](/static/upload/image/20200807/1596737324987693.jpg)

![[pics:title]](/static/upload/image/20200807/1596737324974533.jpg)

![[pics:title]](/static/upload/image/20200921/1600697071437444.jpg)

![[pics:title]](/static/upload/image/20200921/1600697071882056.jpg)

![[pics:title]](/static/upload/image/20200921/1600697071699227.jpg)

![[pics:title]](/static/upload/image/20200921/1600697071746991.jpg)